Foxconn and Intrinsic Join Forces to Build the AI-Enabled Factory of the Future

Hon Hai Technology Group, widely known as Foxconn, and Intrinsic have announced the launch of a joint venture aimed at redefining the next generation of smart factories. This collaboration seeks to bring to life the “factory of the future,” leveraging AI-enabled robotics to transform manufacturing operations. With factories under increasing pressure to be more flexible, adaptive, and cost-efficient, the partnership targets innovations that could reshape how products are made across the electronics sector and beyond.

Harnessing AI for Smarter Manufacturing

The manufacturing sector is experiencing a significant paradigm shift, driven in part by the rapid adoption of artificial intelligence. Robotics has already played a central role in automating repetitive or high-precision tasks, but traditional systems often fall short in handling dynamic, complex production environments. Current automation is typically rigid, tailored for specific product lines, and requires extensive re-engineering to adapt to new models or iterations.

Foxconn and Intrinsic aim to change this by implementing AI-enabled robotics capable of general-purpose tasks and intelligent decision-making. By integrating machine learning, computer vision, and advanced robotics, the goal is to automate processes previously considered too complex or variable for conventional robots. This approach promises not only greater efficiency but also the ability to scale manufacturing quickly in response to surging demand for high-tech electronics.

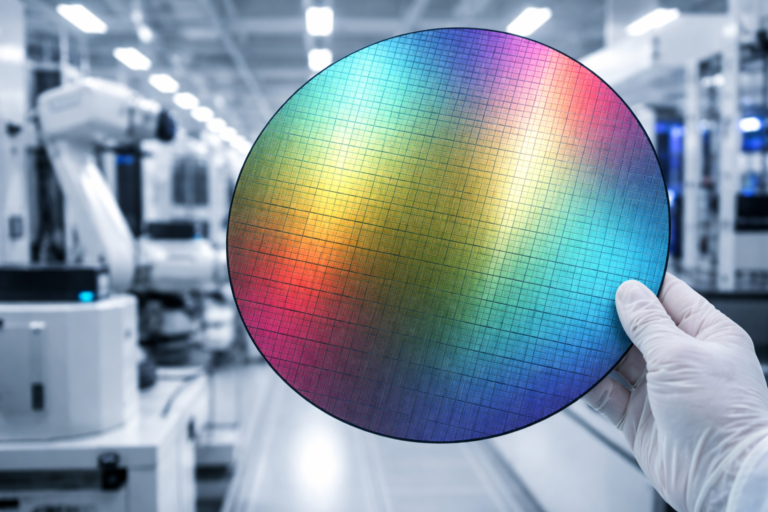

Modernizing Electronics Assembly

The joint venture will focus initially on electronics assembly, an area experiencing exponential growth due to the AI boom. Industries producing server trays, GPUs, and data center components face unprecedented demand, but many factories still rely on a mix of rigid automation and manual labor. Despite being highly technical, AI server manufacturing is not yet fully optimized, leaving significant opportunities for modernization.

By applying AI-driven automation, the Foxconn-Intrinsic partnership seeks to streamline assembly, inspection, machine tending, and logistics applications. These improvements are expected to enhance productivity, reduce errors, and allow factories to respond more quickly to shifts in demand. Moreover, automating tasks that previously required human labor could free skilled workers to focus on higher-level problem-solving and oversight, elevating the role of human expertise in a fully digital factory ecosystem.

From Task-Level Automation to Full Factory Orchestration

A key ambition of this joint venture is to move beyond task-specific automation. Traditional robotic systems are often constrained to repetitive, narrowly defined tasks, which limits their flexibility and long-term utility. The Foxconn-Intrinsic collaboration aims to implement general-purpose intelligent robotics, capable of performing a wide range of activities across different product lines without extensive reprogramming or hardware changes.

This approach could enable factories to transition toward full orchestration, where data-driven insights and AI algorithms optimize production schedules, material handling, and quality control in real time. By integrating robotics, AI, and digital twins, factories can achieve a level of adaptability that was previously unattainable, adjusting instantly to product changes, demand spikes, or supply chain disruptions.

Leveraging Intrinsic Flowstate and AI Capabilities

The joint venture will utilize Intrinsic Flowstate, a web-based developer environment, as a foundational tool for creating AI-enabled solutions. Flowstate provides a common platform for engineers at Foxconn and Intrinsic to collaborate, build, and deploy AI-driven robotics applications efficiently. One of the central capabilities in Flowstate is the Intrinsic Vision Model (IVM), which empowers robots to perceive and interpret their environment with unprecedented accuracy.

With IVM and other AI tools, robots can tackle complex assembly processes that were previously impossible to automate. For example, inspecting small components or dynamically adjusting assembly operations based on real-time data becomes feasible, enhancing both precision and throughput. By embedding intelligence directly into robotic systems, the partnership envisions factories that are not just automated but truly intelligent.

Leadership Perspectives

Young Liu, Chairman and CEO of Foxconn, emphasized the strategic synergy:

“In working with Intrinsic, we are able to tap their deep expertise in AI-driven robotics. This synergy complements our global manufacturing leadership, enabling us to collaboratively unlock the factory of the future.”

Wendy Tan White, CEO of Intrinsic, highlighted the potential for real-world impact:

“Together we’re working to bring the value of AI into the physical world. By marrying Intrinsic’s expertise in AI-driven robotics software—along with Alphabet’s deep knowledge of applied research and platform development—with Foxconn’s global production capabilities and vision for the future of manufacturing, we will accelerate the adoption of AI where it is most needed and valuable today. The partnership with Foxconn provides an incredible opportunity to scale these solutions broadly.”

Dr. Zhe Shi, Chief Digital Officer of Foxconn, elaborated on the operational transformation:

“Intrinsic has led the way in building AI-integrated platforms and scalable AI-enabled robotics. In working together, we’ll ensure Foxconn’s Smart Manufacturing platform enables intelligent automation across our factories—from data management to robotics, AI, and digital twins. This partnership will revolutionize factory operations, making them more flexible, adaptable, skill-based, and scalable. From individual tasks at the robot level to full production lines and plant management, we’re excited to be building the factory of the future together.”

The Bigger Picture: Transforming Global Manufacturing

This joint venture reflects a broader trend in the manufacturing sector, where AI and robotics are becoming central to competitiveness and innovation. By integrating intelligent robotics and data-driven automation, factories can achieve higher efficiency, reduced waste, and faster time-to-market. The Foxconn-Intrinsic partnership exemplifies how combining hardware expertise with AI software capabilities can create scalable, adaptable, and future-ready manufacturing solutions.

Moreover, these advancements are not limited to electronics. Lessons learned from AI-driven assembly and logistics can be applied across sectors such as automotive, consumer electronics, aerospace, and even emerging technologies in advanced manufacturing. As factories evolve to meet global demand, the ability to implement flexible and intelligent solutions will become a defining factor for industry leaders.

Source Link:https://www.foxconn.com/en-us/press-center/press-releases/latest-news/1906