3D-Printed It wasn’t just an idea — it was an idea that wanted to become a reality,” recalls Kate Bergeron, Apple’s vice president of Product Design. “Once the question was raised, the momentum behind it was immediate. We began testing right away. Through relentless prototyping, continuous refinement of the process, and an enormous amount of data collection, we had to prove that this technology could meet the extraordinarily high quality standards Apple expects.

That question — whether advanced 3D-printing techniques could be used to manufacture the most premium Apple Watch cases — marked the beginning of a transformative journey for Apple’s design and engineering teams. In 2026, that journey reaches a milestone: every Apple Watch Ultra 3 case and every titanium Apple Watch Series 11 case is produced through 3D printing using 100 percent recycled aerospace-grade titanium powder, something previously considered impossible at mass-production levels.

Achieving this feat required cooperation and innovation across the entire company. Each team, from materials science to industrial design to environmental strategy, aligned behind a common goal. The Series 11 demanded a flawlessly polished mirror finish that could withstand scrutiny even at close inspection. The Ultra 3 had to maintain the characteristics that define it — outstanding durability, structural strength, and a lightweight feel for athletes, explorers, and daily users alike. And both watches needed to be made from materials that were not only as good as before, but better for the planet.

“At Apple, the environment is a core value for every team,” says Sarah Chandler, Apple’s vice president of Environment and Supply Chain Innovation. “We recognized early on that 3D printing held remarkable potential for improving material efficiency, and that efficiency is critical for achieving Apple 2030.”

Apple 2030, the company’s bold plan, commits Apple to becoming carbon neutral across its entire corporate footprint — from product design and supply chain processes to customer use — by the end of this decade. Much progress has already been made. Today, Apple confirms that 100 percent of the electricity used to manufacture Apple Watch is sourced from renewable energy, including large-scale solar and wind projects around the world.

A Manufacturing Shift Decades in the Making

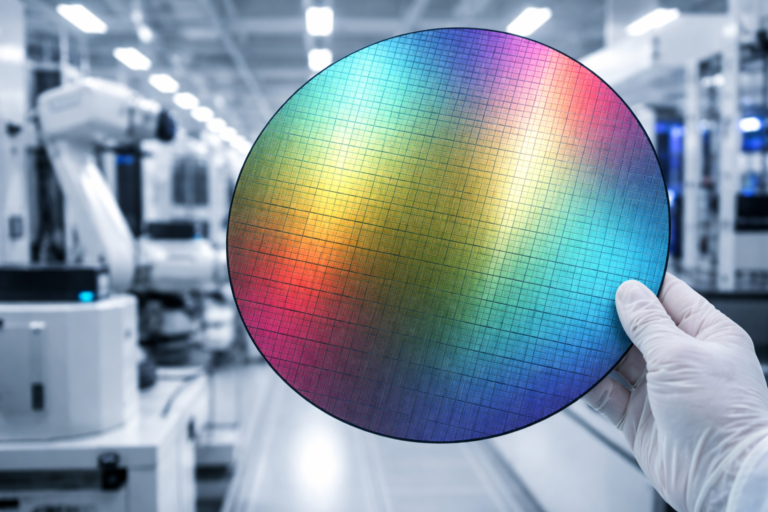

3D printing, or additive manufacturing, works fundamentally differently from traditional machining. Instead of carving, shaving, or cutting away material to reach the desired shape, additive manufacturing builds objects step by step, layering material until the structure matches the final geometry. For products like the Apple Watch, where precision and finish quality are paramount, applying 3D printing at a large scale has always been a daunting challenge.

Traditionally, Apple’s titanium cases were forged and then machined — a subtractive process that removes significant amounts of material. While highly effective, it results in considerable waste. With the new additive titanium process, the Ultra 3 and Series 11 cases achieve nearly their final form directly through printing. This shift cuts raw material usage in half compared to previous manufacturing generations.

“A 50 percent reduction is a massive achievement,” Chandler explains. “It ultimately means you can produce two watch cases using the same amount of material that previously produced only one. When you consider that difference at global scale, the environmental benefit becomes enormous.”

Apple estimates that more than 400 metric tons of raw titanium will be saved in 2026 alone due to this new method — a figure that represents not only material efficiency but also a reduced carbon footprint across mining, refining, and transportation processes.

From Experiments to Breakthroughs

Apple’s interest in 3D printing is not new. Over the past decade, the company had been quietly experimenting with additive manufacturing while watching the technology mature in the broader world. Medical researchers began using early 3D-printed prosthetics and artificial organ models. Aerospace engineers explored printing components for rockets and satellites. Even astronauts aboard the International Space Station turned to 3D printing to rapidly produce tools and parts in orbit.

“We’ve observed this technology evolve for a long time,” says Dr. J Manjunathaiah, Apple’s senior director of Manufacturing Design for Apple Watch and Vision. “Each year we saw prototypes become more sophisticated and increasingly aligned with the type of designs we wanted to build. Using less material has always been a priority for us. But until recently, 3D printing wasn’t capable of delivering cosmetic parts at the scale and quality Apple requires.”

That limitation inspired Apple’s materials and manufacturing teams to take on the challenge directly. They began testing 3D-printed metal components, experimenting with different titanium powders, fusion techniques, and post-processing steps needed to produce cases with the right look and feel. This required breakthroughs not only in equipment and processes but in the science of materials themselves.

A Balance of Beauty, Strength, and Sustainability

For Apple, any new manufacturing technique must meet a long checklist of requirements. The final part must be beautiful enough to meet the company’s strict design standards, durable enough to endure years of wear, and strong enough to protect the device’s intricate internal components. It must also scale — Apple products are manufactured at a volume few companies attempt — and meet rigorous reliability and safety thresholds. And overarching all of this is the company’s commitment to sustainability, especially as it works toward Apple 2030.

3D printing titanium watch cases meant redefining nearly every step of production. Engineers worked tirelessly to refine printing parameters, ensuring microscopic layers fused uniformly to form a solid, high-strength structure. New finishing processes were developed to achieve the Series 11’s mirror polish and the Ultra 3’s rugged exterior. Quality control teams built new inspection systems capable of analyzing 3D-printed surfaces at a level of precision measured in microns.

The result is a pair of products that embody Apple’s historic blend of form and function: beautiful to look at, extremely durable, and now dramatically more efficient to produce.

A New Standard for the Future

Apple’s adoption of large-scale 3D-printed titanium represents more than a manufacturing milestone — it signals a shift in how the company, and potentially the industry, thinks about product creation. Additive manufacturing allows for design possibilities that traditional machining cannot match. It reduces waste, enables faster iteration, and opens the door to more sustainable materials.

For Apple, this is only the beginning. As Bergeron puts it, “Once the idea emerged, it had a momentum of its own.” Every advancement in additive titanium builds the foundation for future innovations, not just for Apple Watch, but for other product categories where strength, precision, and sustainability converge.

By combining engineering ambition, environmental responsibility, and a willingness to reimagine decades-old manufacturing practices, Apple has turned what was once experimental into a new reality — one built layer by layer.

Source Link:https://www.apple.com/newsroom/2025/