Wolfspeed Marks Major Industry Milestone with 300mm Silicon Carbide Wafer Breakthrough

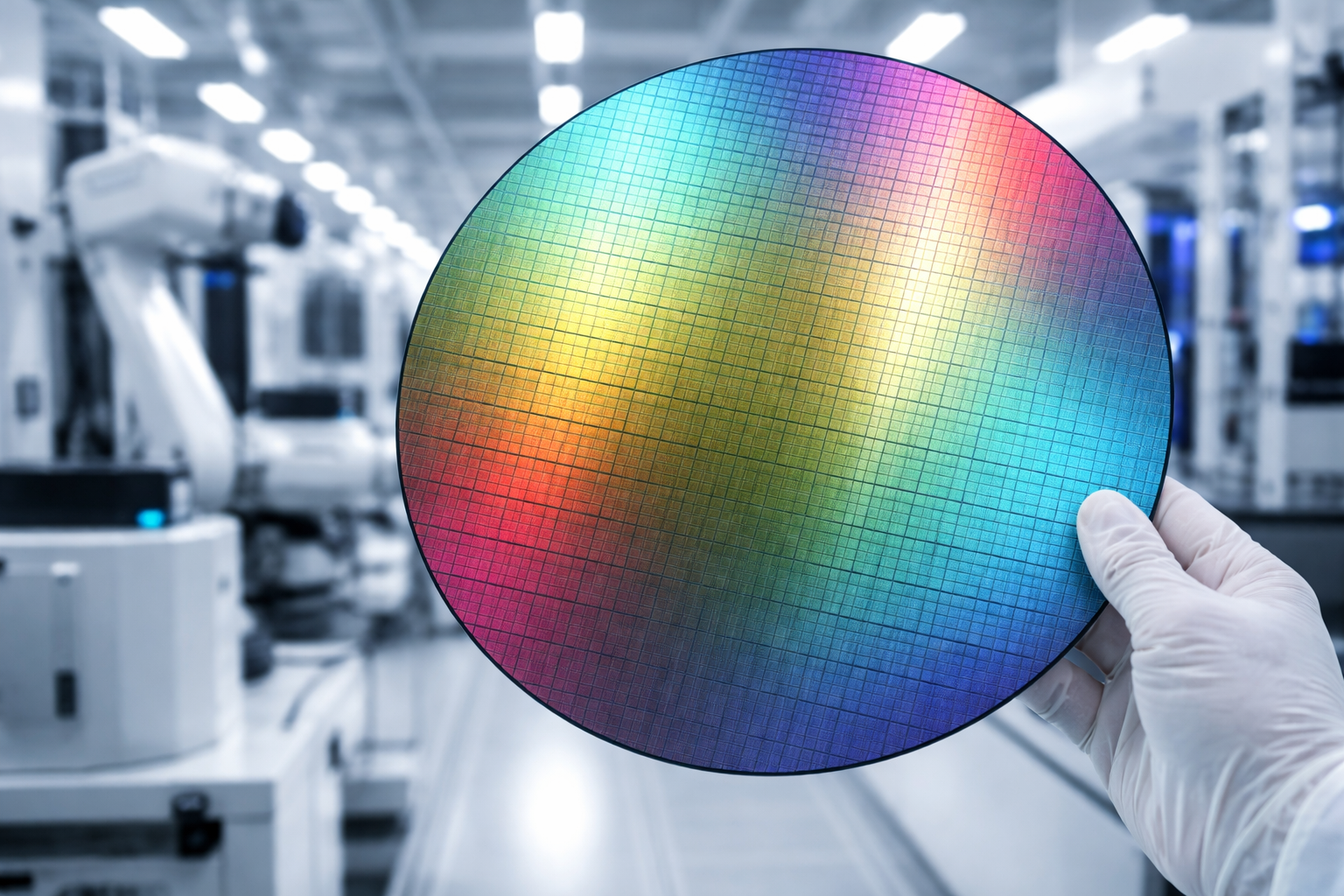

Wolfspeed, Inc. a global pioneer in silicon carbide (SiC) technology, has reached a historic milestone in the semiconductor industry with the successful production of a single-crystal 300mm (12-inch) silicon carbide wafer. This breakthrough positions Wolfspeed at the forefront of next-generation semiconductor manufacturing and signals a transformative shift in how advanced materials will power future technologies.

Supported by one of the world’s most extensive silicon carbide intellectual property portfolios—comprising more than 2,300 issued and pending patents—Wolfspeed is accelerating the industry’s transition toward 300mm SiC technology. This advancement establishes a strong foundation for future large-scale commercialization, unlocking unprecedented opportunities for performance, scalability, and cost efficiency across multiple high-growth markets.

A New Era for Silicon Carbide Manufacturing

For decades, silicon carbide has been recognized as a critical material for high-performance semiconductor applications due to its superior electrical, thermal, and mechanical properties compared to traditional silicon. However, the industry has historically relied on smaller wafer sizes—typically 150mm and more recently 200mm—limiting manufacturing efficiency and scalability.

By achieving a single-crystal 300mm silicon carbide wafer, Wolfspeed has overcome one of the most complex technical challenges in compound semiconductor manufacturing. Producing such large-diameter SiC wafers requires breakthroughs in crystal growth, boule formation, defect control, and wafer processing, areas that have traditionally constrained the industry’s progress.

This achievement represents more than a technical milestone—it marks a structural shift in the semiconductor ecosystem. Larger wafers enable higher chip yields per wafer, improved manufacturing economics, and greater production throughput. As a result, the transition to 300mm silicon carbide has the potential to redefine cost structures and accelerate adoption across industries ranging from artificial intelligence and immersive computing to power electronics and advanced communications.

Driving Innovation Across Next-Generation Technologies

The implications of Wolfspeed’s 300mm SiC breakthrough extend far beyond manufacturing efficiency. The technology opens new performance thresholds for some of the world’s most demanding semiconductor applications, including artificial intelligence (AI), augmented and virtual reality (AR/VR), high-voltage power systems, and next-generation computing platforms.

Silicon carbide’s ability to operate at higher voltages, temperatures, and frequencies than silicon makes it uniquely suited for applications where efficiency and reliability are critical. By scaling SiC technology to 300mm wafers, Wolfspeed is enabling a new class of semiconductor devices that can deliver greater power density, improved thermal performance, and enhanced system integration.

“Producing a 300mm single-crystal silicon carbide wafer is a significant technology achievement and the result of years of focused innovation in crystal growth, boule development, and wafer processing,” said Elif Balkas, Chief Technology Officer at Wolfspeed. “This milestone positions Wolfspeed to support the industry’s most transformative technologies, particularly critical components of the AI ecosystem, immersive augmented and virtual reality systems, and advanced power device applications.”

Unifying Power Electronics and Advanced Substrate Technologies

One of the most compelling aspects of Wolfspeed’s 300mm platform is its ability to unify multiple semiconductor domains within a single manufacturing framework. The company’s approach integrates high-volume silicon carbide manufacturing for power electronics with advanced capabilities in high-purity semi-insulating substrates used in optical and radio-frequency (RF) systems.

This convergence enables wafer-scale integration across optical, photonic, thermal, and power domains—an essential capability for future semiconductor architectures. By bringing these technologies together on a single platform, Wolfspeed is laying the groundwork for highly integrated systems that can deliver superior performance while reducing complexity and cost.

Such integration is particularly important as the semiconductor industry moves beyond traditional transistor scaling. As Moore’s Law slows, innovation increasingly depends on new materials, advanced packaging, and system-level integration. Wolfspeed’s 300mm silicon carbide technology represents a critical step in this evolution.

Empowering the AI Revolution: More Than Moore

Artificial intelligence workloads are rapidly pushing data centers to their limits. The exponential growth in computing demand has created unprecedented challenges in power consumption, heat dissipation, and energy efficiency. Traditional silicon-based power delivery systems are struggling to keep pace with these requirements.

Wolfspeed’s 300mm silicon carbide technology offers a powerful solution. By enabling high-voltage power delivery systems, advanced thermal management, and active interconnects at wafer scale, SiC technology can significantly improve the efficiency and performance of AI infrastructure.

This approach aligns with the concept of “More Than Moore,” where innovation extends beyond transistor miniaturization to include new materials, architectures, and integration techniques. Silicon carbide’s unique properties—such as wide bandgap, high breakdown voltage, and exceptional thermal conductivity—make it a cornerstone of this paradigm.

As AI continues to reshape industries ranging from cloud computing and autonomous systems to scientific research and generative technologies, the demand for efficient and scalable power solutions will only intensify. Wolfspeed’s 300mm SiC platform positions the company as a key enabler of this transformation.

Transforming AR/VR Through Optical and Thermal Integration

Beyond AI, Wolfspeed’s breakthrough has significant implications for immersive technologies such as augmented reality and virtual reality. Next-generation AR/VR systems require compact, lightweight designs that integrate high-brightness displays, wide fields of view, and effective thermal management within tightly constrained form factors.

Silicon carbide’s material properties make it uniquely suited for these challenges. Its mechanical strength, thermal conductivity, and optical refractive control enable multifunctional optical architectures that can deliver superior performance while maintaining compactness and durability.

By scaling SiC technology to 300mm wafers, Wolfspeed is enabling the production of advanced optical and photonic components at unprecedented scale. This capability could accelerate the development of next-generation AR/VR devices that are more powerful, energy-efficient, and immersive than ever before.

Accelerating the Future of Power Electronics

While AI and immersive computing represent high-profile applications, the impact of 300mm silicon carbide technology on power electronics may be even more profound. Silicon carbide is already transforming industries such as electric vehicles, renewable energy, industrial automation, and high-voltage power transmission.

The transition to 300mm wafers significantly enhances the industry’s ability to meet growing demand for advanced power devices. Larger wafers improve manufacturing efficiency and reduce per-device costs, making SiC-based solutions more accessible across a wide range of applications.

In sectors such as electric grids and industrial systems, silicon carbide devices offer higher efficiency, reduced energy losses, and improved reliability. These advantages are critical as global electrification accelerates and industries seek to reduce carbon emissions while increasing performance.

By pioneering the shift to 300mm SiC technology, Wolfspeed is helping to scale the production of advanced power devices at a pace that aligns with global demand for electrification and sustainability.

Industry Validation and Market Implications

Industry experts have recognized the significance of Wolfspeed’s achievement as a turning point for the compound semiconductor market. Poshun Chiu, Principal Analyst for Compound Semiconductors at Yole Group, highlighted the broader implications of the breakthrough:

“This 300mm milestone is more than a technical achievement—it unlocks new opportunities for silicon carbide as a strategic material. It clearly demonstrates that silicon carbide is advancing to the next level of manufacturing maturity required for the coming decade of electrification, digitalization, and artificial intelligence. It provides the market with a credible roadmap toward higher-volume production, improved economics, and long-term supply assurance.”

This validation underscores the strategic importance of Wolfspeed’s innovation not only for the company but also for the global semiconductor ecosystem. As industries increasingly depend on advanced materials to meet performance and sustainability goals, silicon carbide is emerging as a foundational technology.

Building the Foundation for the Next Decade of Semiconductors

Wolfspeed’s 300mm silicon carbide wafer breakthrough represents a convergence of technological innovation, manufacturing expertise, and strategic vision. By pushing the boundaries of what is possible in compound semiconductor manufacturing, the company is setting the stage for a new era of semiconductor design and production.

The transition to 300mm SiC technology is expected to accelerate the adoption of silicon carbide across multiple industries, driving advancements in AI, immersive computing, power electronics, and beyond. It also provides the semiconductor industry with a scalable and economically viable path toward meeting the demands of the next decade.

As Wolfspeed continues to refine and commercialize its 300mm platform, the implications of this breakthrough will ripple across the global technology landscape. From data centers and smart grids to autonomous systems and immersive devices, silicon carbide is poised to play a central role in shaping the future of electronics.

With this milestone, Wolfspeed has not only demonstrated technical leadership but also reaffirmed its commitment to driving innovation in wide-bandgap semiconductors. The successful production of a single-crystal 300mm silicon carbide wafer marks a decisive step forward—one that could redefine the trajectory of the semiconductor industry for years to come.

Source Link:https://www.businesswire.com/